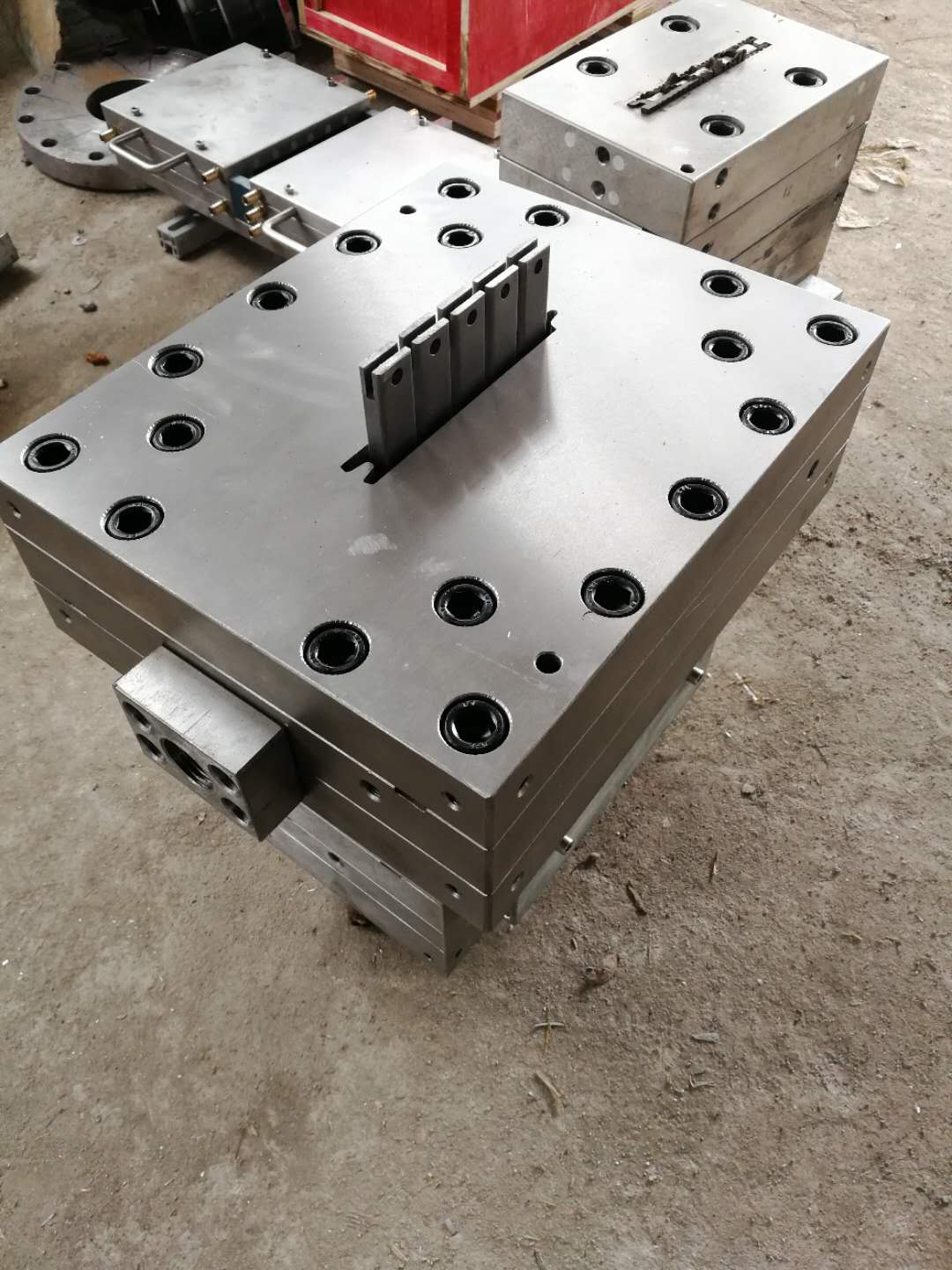

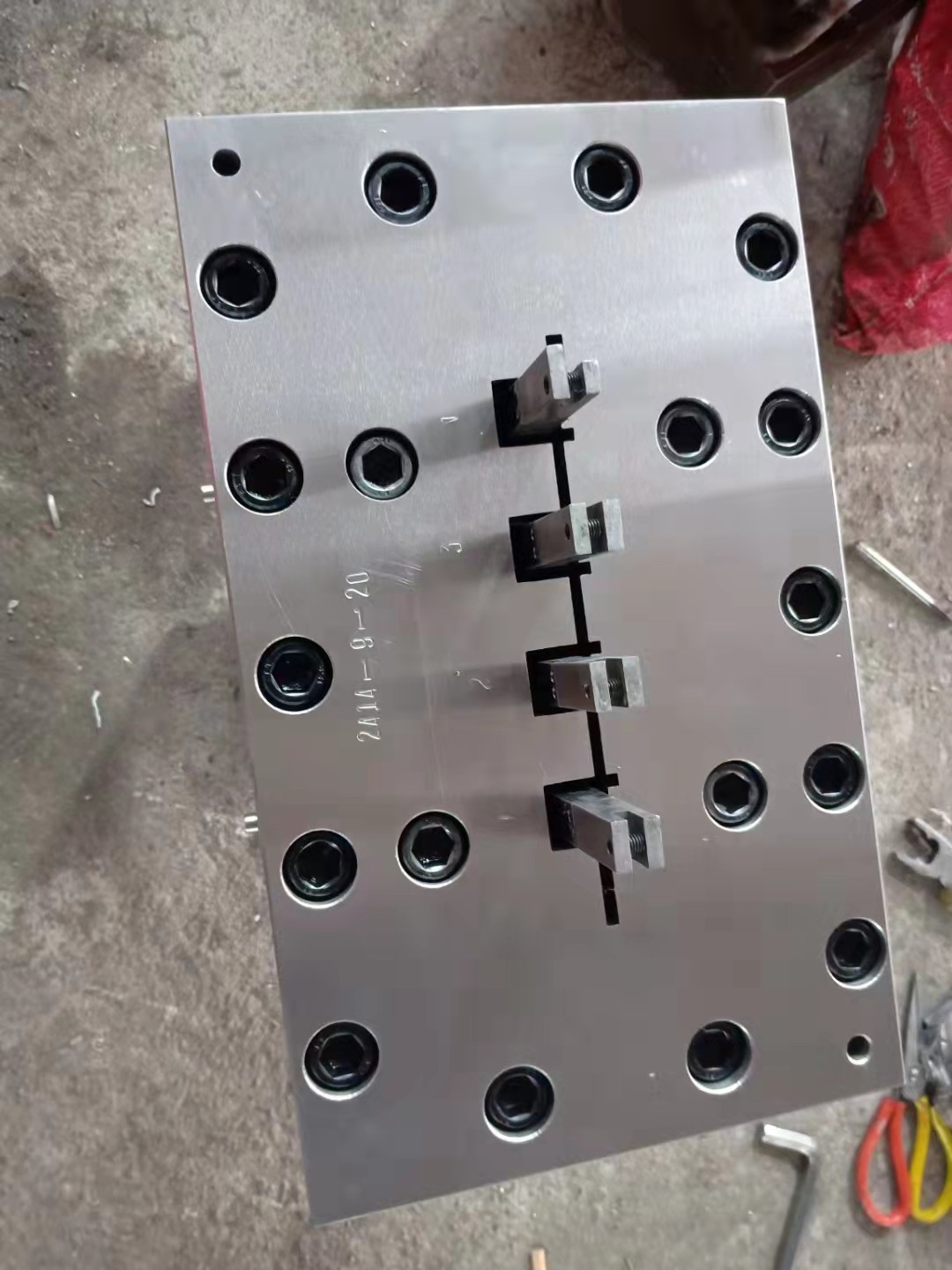

1.Durable material for moulds and mould can working longer time with right weight and can save cost for clients.

2.Usually mould working speed would higher and can have a bigger capability to help clients to get big orders from they clients.

3.Can design complex profiles moulds for clients with our long term experiences,help our clients to get high profit order for new products on market.

4.Most of our moulds are stable and our client's workers can operate them smoothly and make it competetive.

1. Capstock: A polymer or blend of polymers placed in a thin layer on the surface of WPC wood plastic profile.

2. Applications:capstock products are designed to be coextruded over Wood-Plastic Composite deck boards to provide moisture & wear resistance, aesthetics, durability and unprecedented adhesion to the WPC substrate.

3. CAPSTOCKS PROTECTIVE COMPOUNDS Custom designed for your desired look, feel and performance. Unrivaled Processability Scratch / Mar / Scuff Resistant Outstanding Substrate Adhesion Premium Weatherability and Durability Custom Matte / Gloss Properties

The classification of the capstock

1,Capstock for WPC hollow decking

2,Capstock for WPC solid decking

3,Capstock for WPC pillar/column

4,Capstock for WPC handrail/railing

5,Capstock for WPC panel/board

6,Capstock for WPC wall panels

7,Capstock for WPC profile

8,Capstock for WPC CO-Extrusion profile