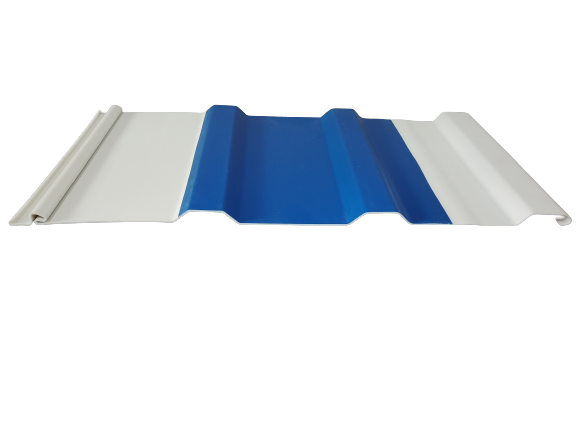

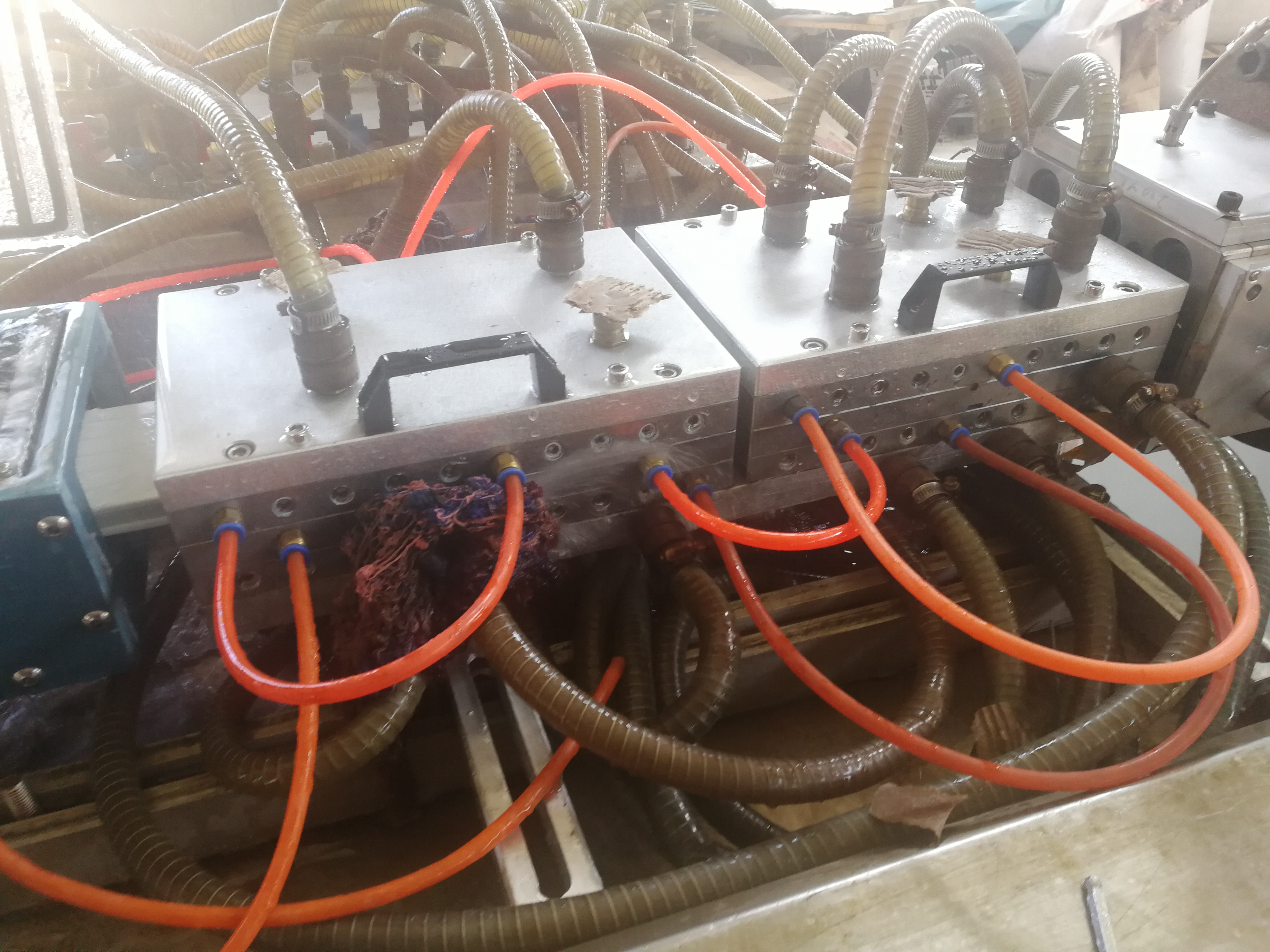

PVC wall panel mold Extrusion Mold plastic die extrusion wall hanging board

1.Durable material for moulds and mould can working longer time with right weight and can save cost for clients.

2.Usually mould working speed would higher and can have a bigger capability to help clients to get big orders from they clients.

3.Can design complex profiles moulds for clients with our long term experiences,help our clients to get high profit order for new products on market.

4.Most of our moulds are stable and our client's workers can operate them smoothly and make it competetive.

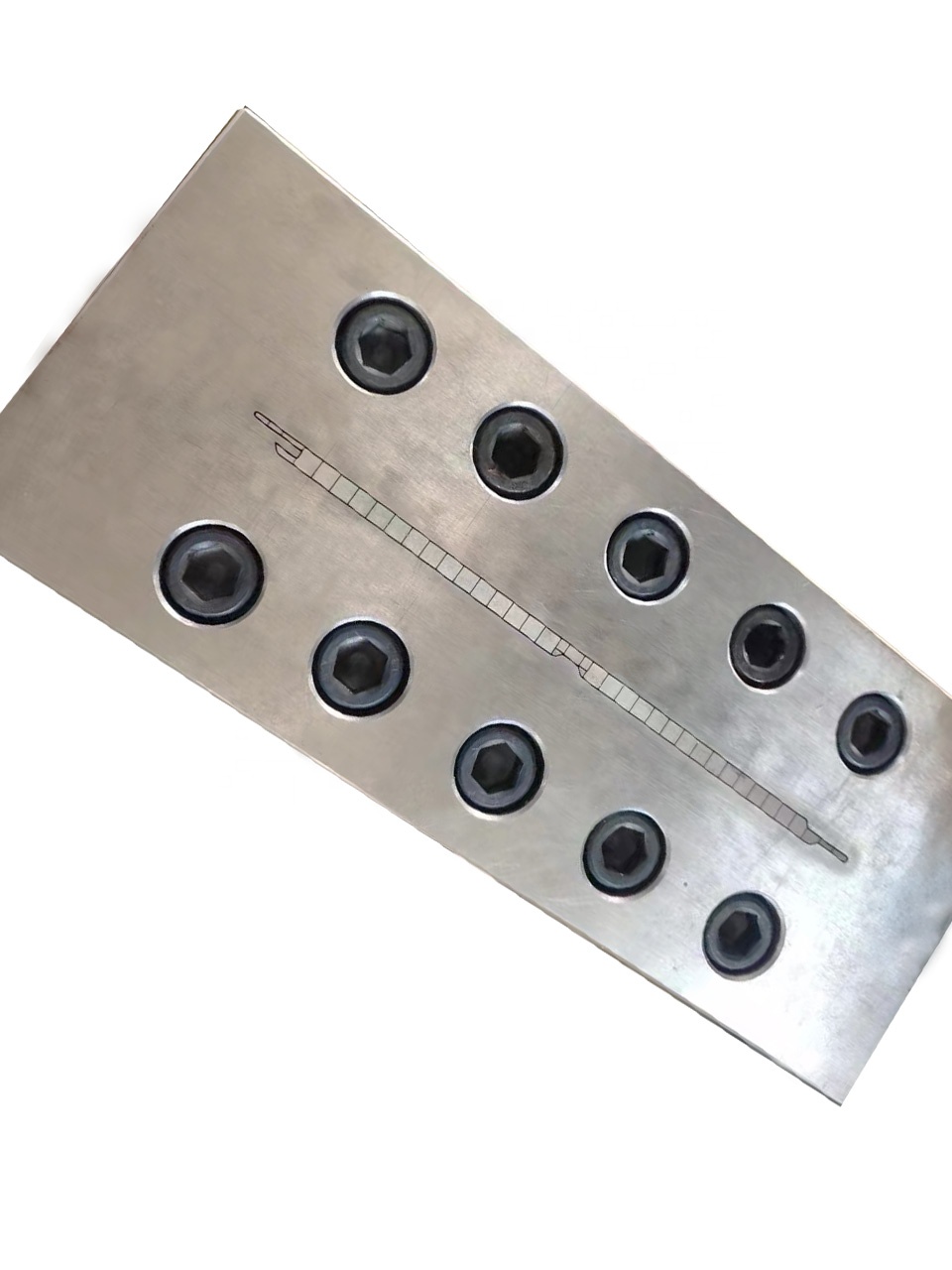

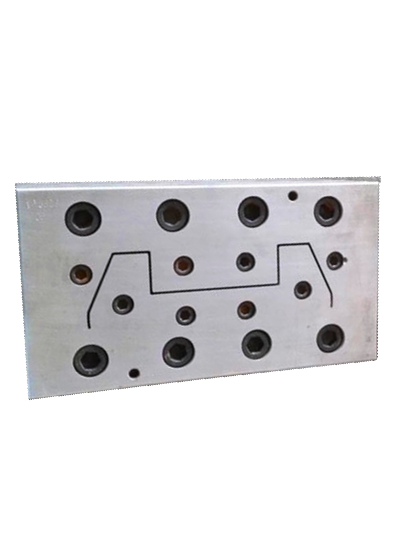

Mould material | 2Cr13,3Cr13,3Cr17,3Cr17Nimo,Din1.2316 as per your request |

Size | Various types |

Mould cavity | 1 or multi-cavity |

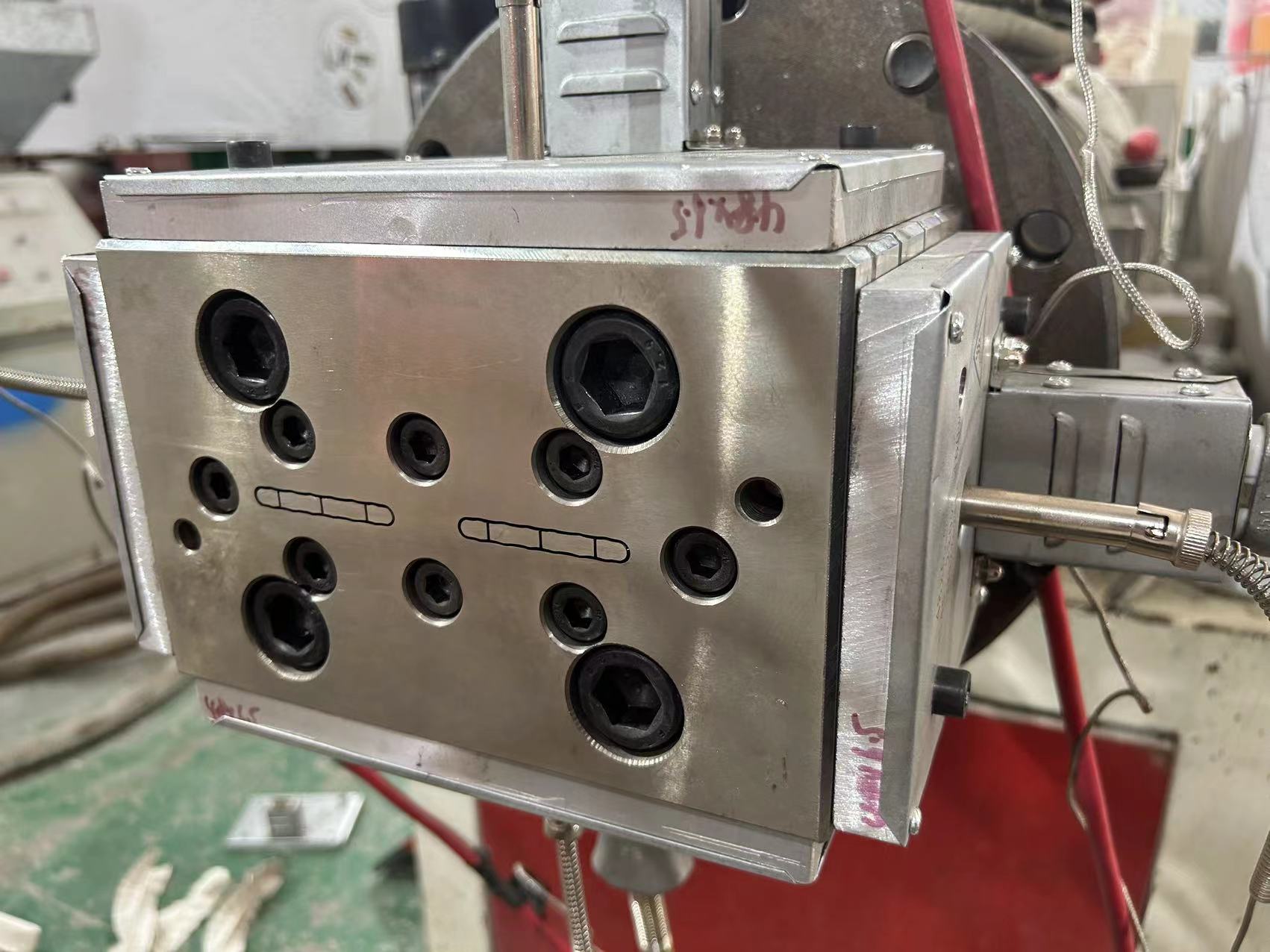

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Features | Selectable co-extrusion of different raw materials: PVC WPC Selectable technology: low-foaming, high-foaming & substance co-extrusionStable discharging, high efficiency, superior quality |

Test | Mould will be tested to get the satisfied sample before delivery |

Service | Provide complete set of production process and technology transfer service |

Lead time | 20-35 days |

Package | Wooden case for exporting, each mould will be cleaned before packaging |

Application | Architecture decorative panel; wall panel;Shutter; landscape construction |