1.Durable material for moulds and mould can working longer time with right weight and can save cost for clients.

2.Usually mould working speed would higher and can have a bigger capability to help clients to get big orders from they clients.

3.Can design complex profiles moulds for clients with our long term experiences,help our clients to get high profit order for new products on market.

4.Most of our moulds are stable and our client's workers can operate them smoothly and make it competetive.

Production Introduction:

Name | WPC Extrusion Profile Mould/WPC Profile Die/WPC Profile Mould and Extrusion Line die tooling |

Size | Various Sizes as Per Customer Require |

Mould Material | 3Cr17, 3Cr17MoNiV, DIN1.2316 or Negotiable |

Mould Cavity | One or Multi-Cavity |

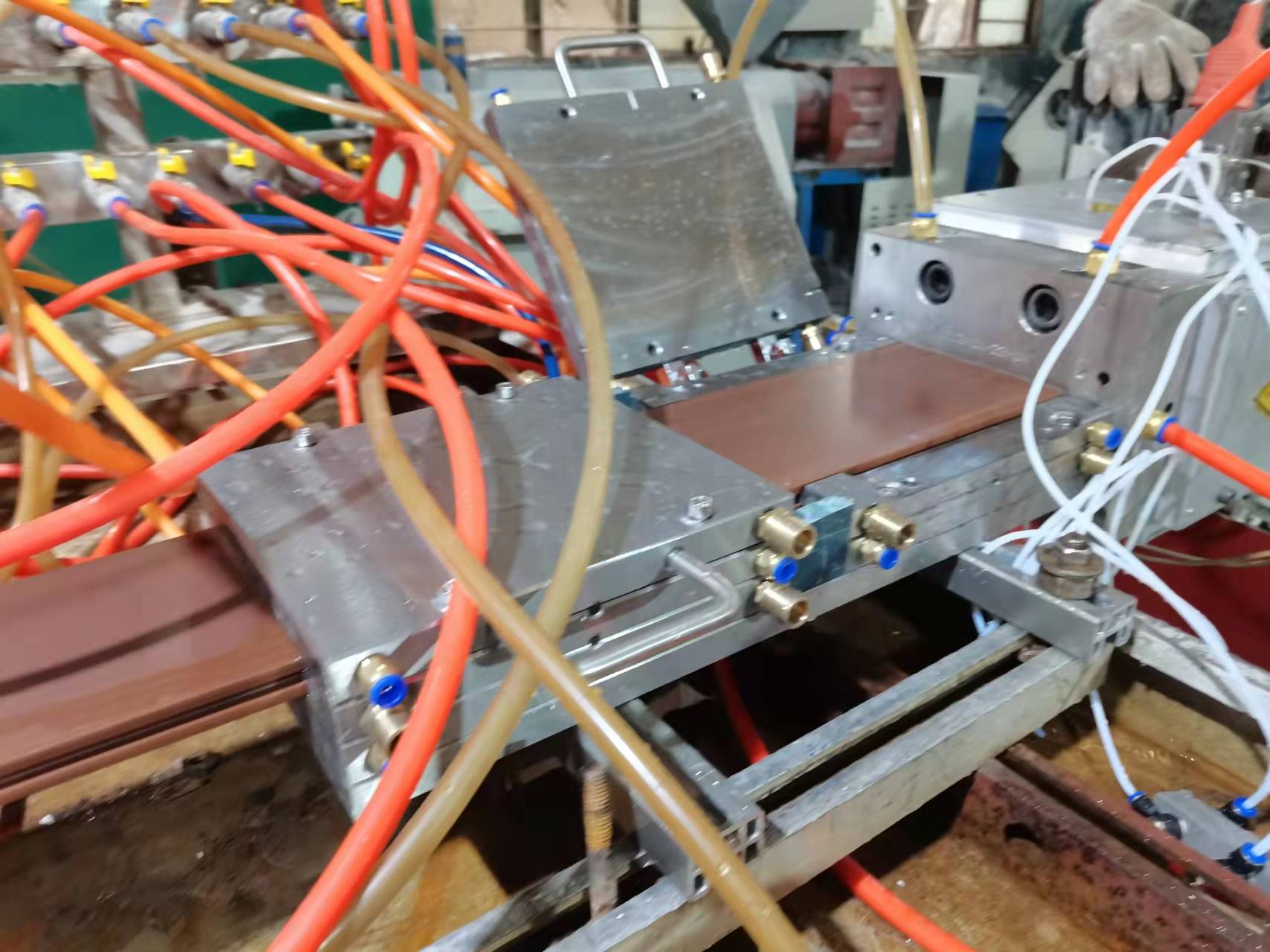

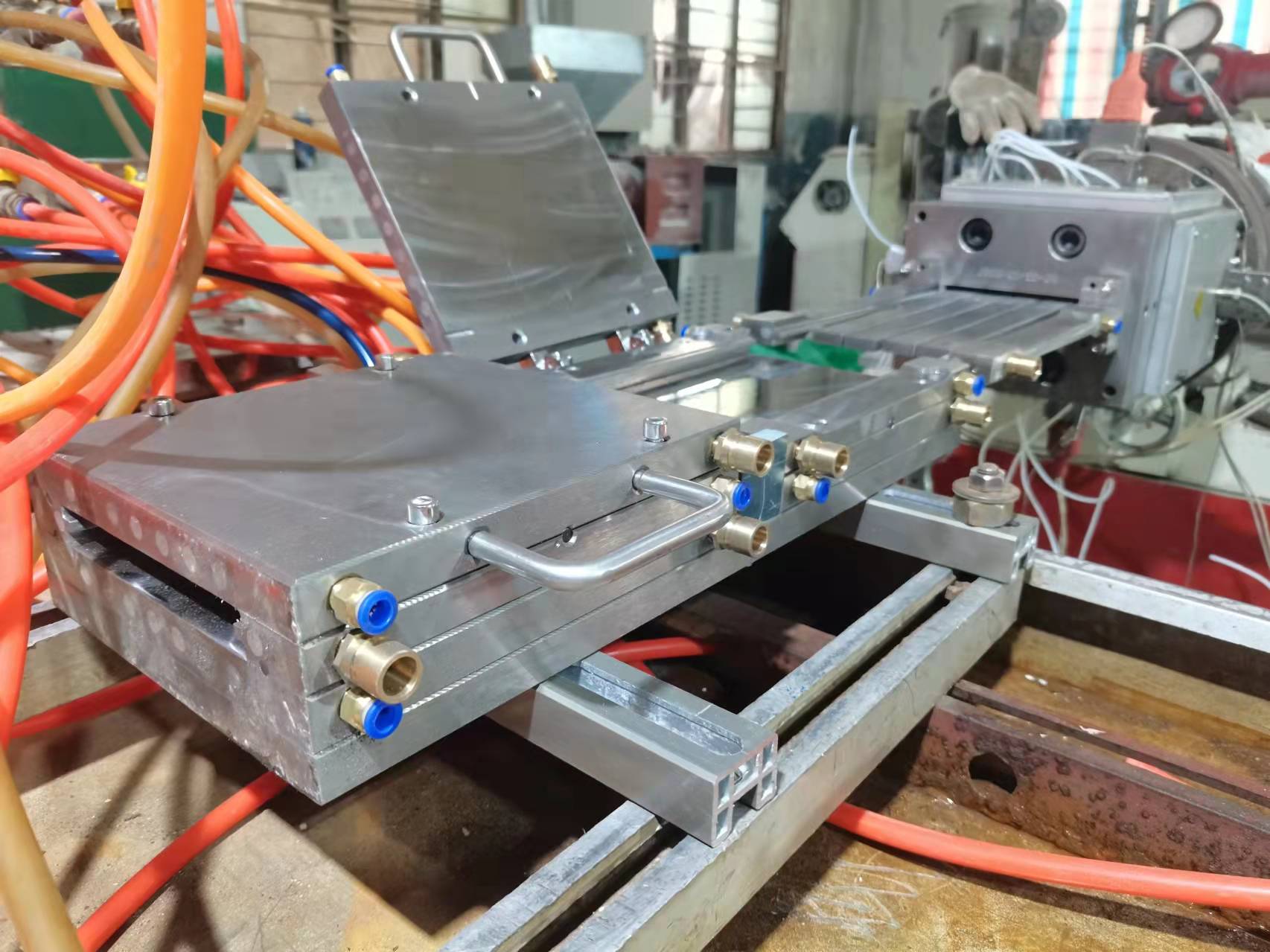

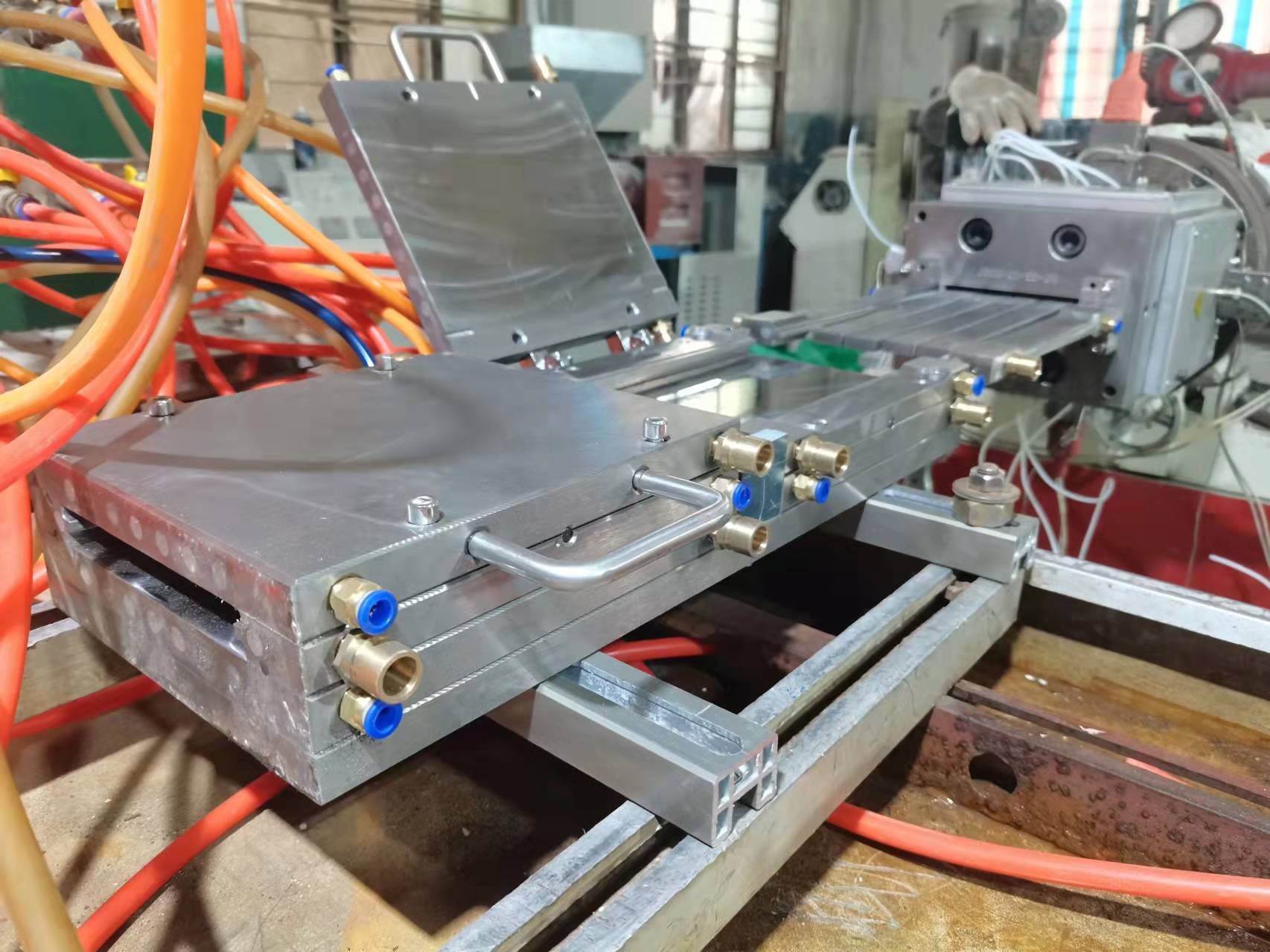

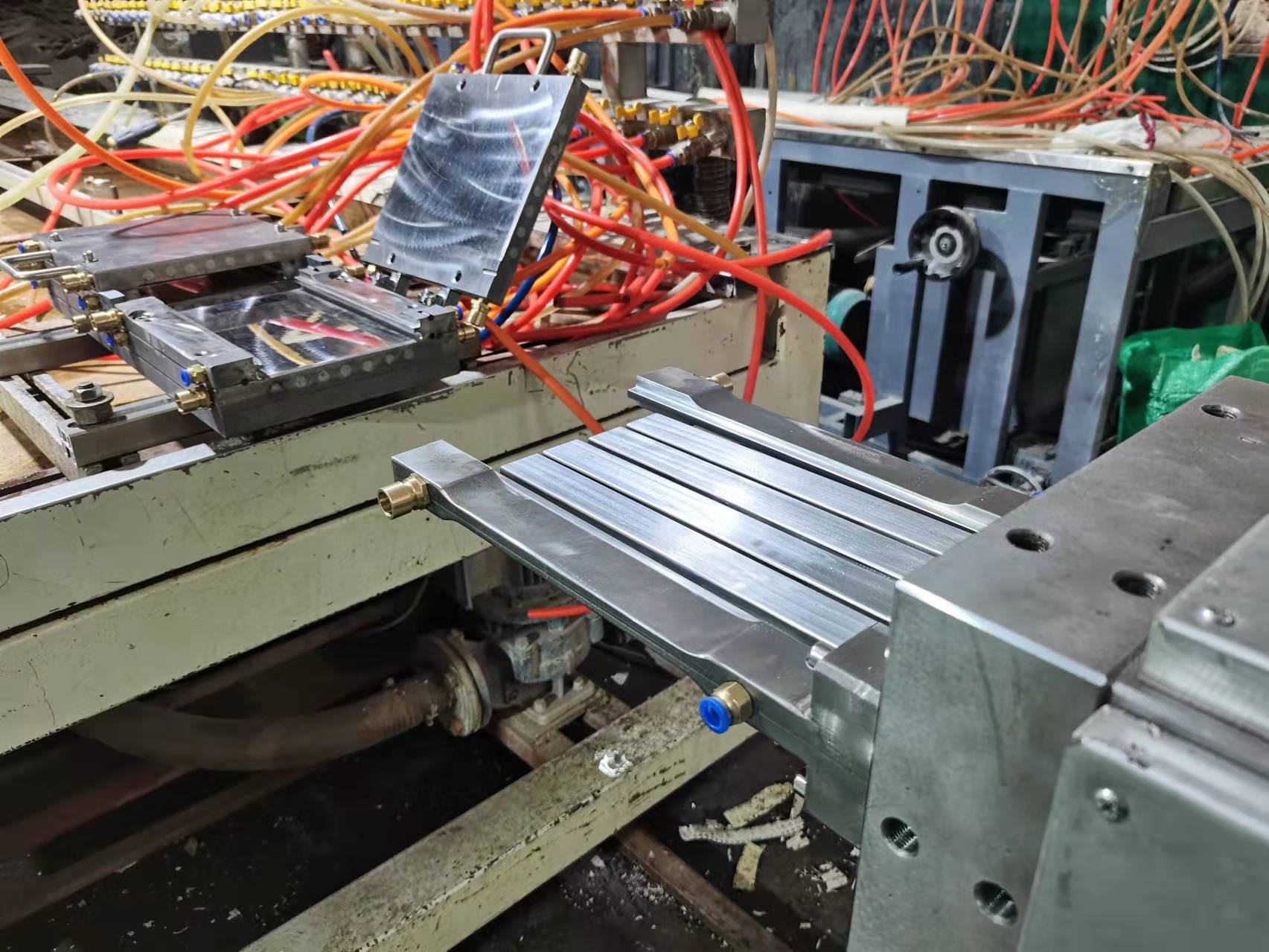

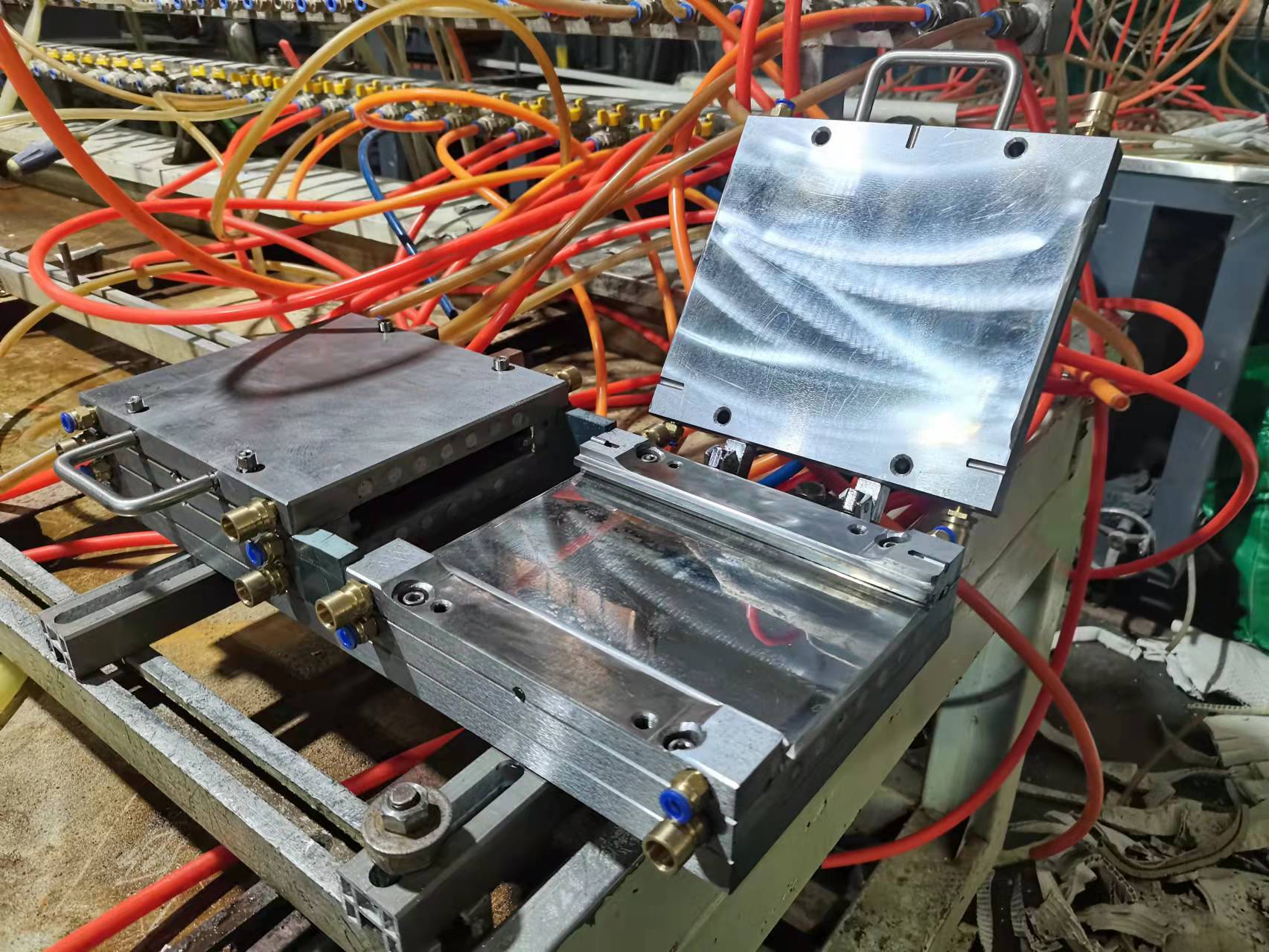

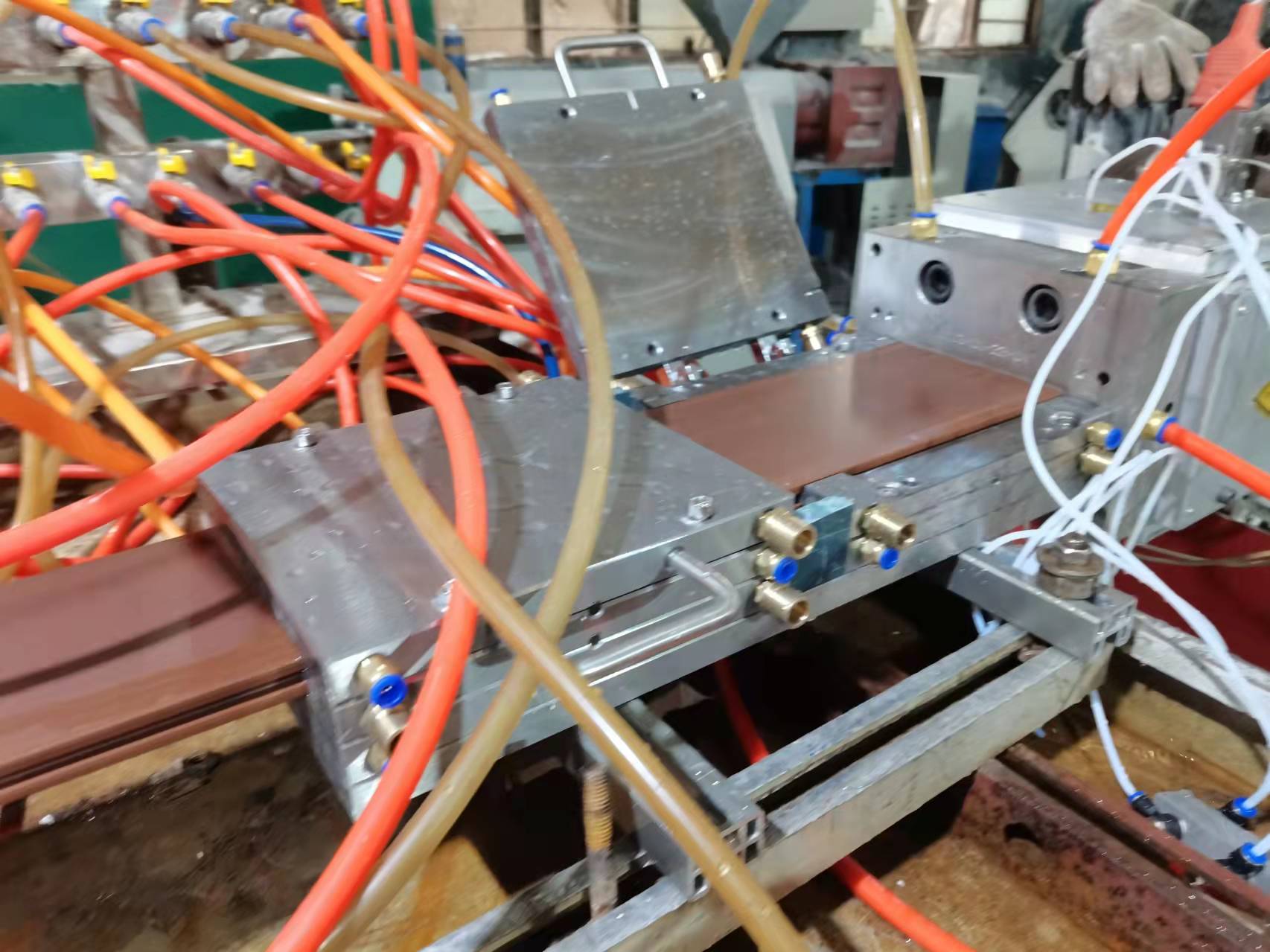

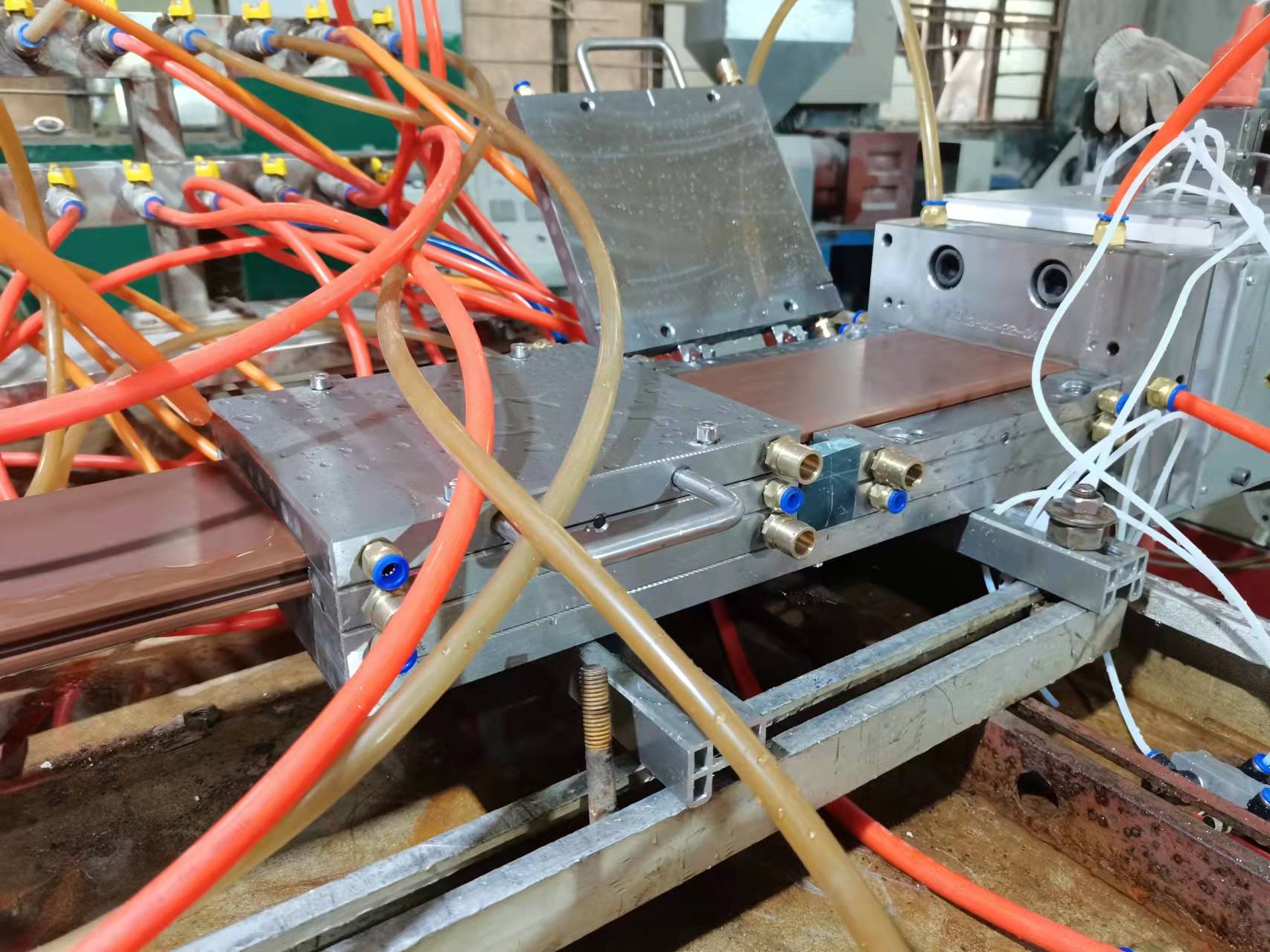

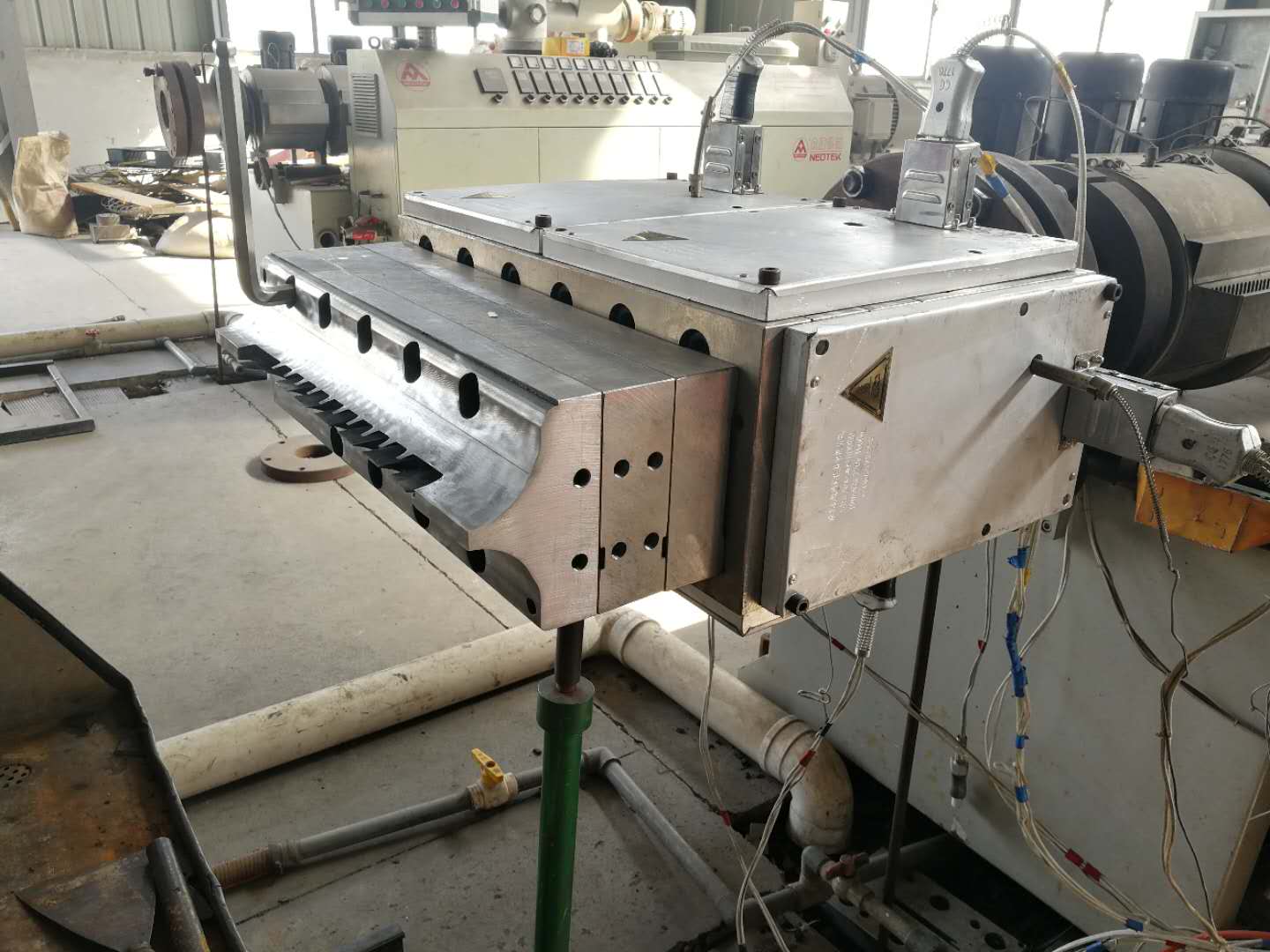

Mould Composition | Die Head, Aluminum Heating Panels, Calibrators and Water Tank |

Feature | High Polished Surface, Stable Discharging, Soft-hard, Surface Layer, Cladding |

Test | Mould will be tested to get the satisfy sample before delivery |

Sample | Sample will be arranged by express for customer approval |

Service | Provide complete set of formulation, technology and perfect after sale service |

Lead time | 15-35days |

Package & deliver | Poly wood case for exporting, each mould will be cleaned before packing. |

Remark : If you are interesting in mould and plastic prodcuts, welcome you provide us the details of the product material , size , weight ect, better 2D and 3D drawing. Welcome you to visit us. | |

The Composition and Function of each part for Extrusion Mould :

Configuration of Mould | Functions | Types |

Dies head | Produce continuous,stable,homogeneous profile | Wear resistance material and mainly with water cooling system |

Calibrators | Cool down and form the profile, the smaller the resistance is ,the better | The quantity of calibrator parts are decided by profile, and extrusion speed. |

Water tank | Cool down the profile further | ,Usually stainless steel material watertank for PE wpc profiles, fiber glass vaccumming water tank for PVC profiles. |